3D-Printed Construction: LSU Team Aims to Revolutionize Housing on Earth — and Beyond

October 09, 2024

Current construction practices can be slow, labor-intensive, and expensive, especially in challenging environments. However, a group of LSU researchers and students is working on solutions using 3D printing — with implications for affordable housing, hurricane recovery, coastal protection, and even space exploration.

“I believe that over the next 10 years, we will see the development of more reliable and intelligent robotic 3D printers, along with complementary robotic capabilities to automate a broader range of construction tasks.”

— Ali Kazemian, assistant professor, LSU's Bert S. Turner Department of Construction Management

The construction industry’s continued reliance on manual operations, along with a growing shortage of skilled labor, has led to rising housing costs and a global housing crisis.

“If you think about how ancient structures were constructed versus how we build with concrete today, you will not find a fundamental change, which is surprising considering the importance of the construction industry in the global economy,” said Ali Kazemian, an assistant professor in LSU's Bert S. Turner Department of Construction Management.

But innovation and a fresh look at how we build structures can allow us to build quality homes faster and at a lower cost. Kazemian heads a team at LSU exploring that potential through their work in construction 3D printing.

While construction using 3D printing is not a new concept, it has received significant attention from both industry and academia in recent years as a "platform" technology with applications in housing, infrastructure development, disaster response, coastal protection, military, and space exploration.

“Initially, there was considerable ‘hype’ surrounding the technology, often amplified by exaggerated claims about its capabilities,” Kazemian said. “But the industry has now reached a stage where there is a more balanced and realistic understanding of the technology, its capabilities, limitations, and the existing challenges.” .

“This technology can improve our quality of life by providing more resilient and affordable housing solutions, while benefiting our society and the economy.”

— Ali Kazemian

Addressing State and Global Problems

Construction 3D printing research conducted at LSU can be part of the solution to the global housing shortage.

“With reliable and versatile construction robots, we can build homes faster and cheaper,” Kazemian said. “Additionally, shelters can be 3D printed at a lower cost compared to traditional construction methods, providing housing for over 600,000 homeless people currently living in the U.S.”

Kazemian said 3D printing is a viable solution for building durable coastal structures that can protect and preserve Louisiana’s shoreline.

Also, following natural disasters such as hurricanes, 3D printing robots can be deployed to rapidly and efficiently build temporary or permanent shelters for those affected, Kazemian said. This also translates well to the military, which often requires sturdy shelters in inhospitable places.

In these extreme environments, relying on humans to perform difficult and hazardous construction tasks is unsafe and impractical. In these scenarios, robotic 3D printing offers a feasible solution for fabricating and constructing structures.

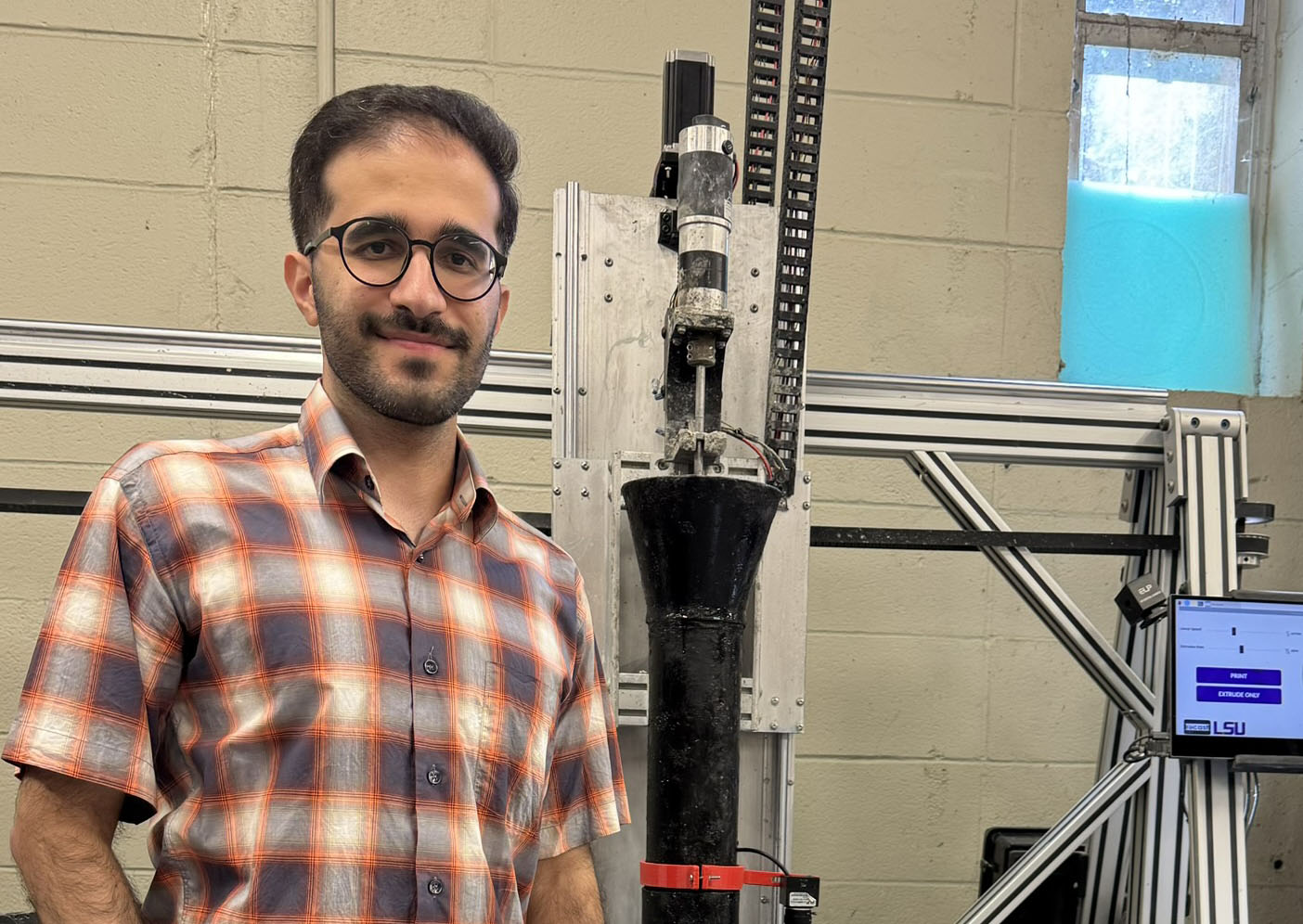

Ph.D. student Kasra Banijamali's research is focused on automated quality control during the robotic 3D printing process.

While current robotic 3D printers are somewhat limited to wall (shell) construction, the LSU team is working to develop additional automated and robotic capabilities, including multi-function robots and approaches to automate a wider variety of construction operations.

Ph.D. student Kasra Banijamali, a member of the research team, says the hands-on experience and knowledge he has received through his work has allowed him to see first-hand the potential of automation in the construction industry.

“Fully automated robotic construction systems can construct durable, low-cost housing in just a few days,” he said, “providing immediate shelter and stability for communities in need.”

How Does Construction 3D Printing Work?

The process begins with a 3D model of the structure to be printed, which is designed on a computer and then processed to generate printing paths for each layer. Commands are sent to the robot, which follows these paths to deposit the printing material — concrete is most widely used — and build the structure layer by layer.

The Challenges of Outer Space

One LSU team project involves working with NASA to develop a process for creating structures for future habitation on the moon, and eventually Mars.

“NASA is planning to establish a long-term presence on the moon in the coming years, which is crucial to advancing space exploration and scientific discovery,” Kazemian said. “But to make this happen, we will need to build infrastructure on the moon such as landing pads, habitats, and radiation shields.”

Building structures on the moon and beyond presents unique challenges not seen on Earth, including:

- limited availability of water and Portland cement, a finely ground powder that's a key ingredient in concrete, mortar, plaster, stucco, and grout;

- inhospitable lunar conditions;

- limited human workforce;

- restricted mobility of suited astronauts.

Given these factors, NASA has identified “robotic construction using the existing resources on the moon” as a feasible direction to tackle this challenge. The LSU team is working to make that a reality.

“To support upcoming NASA missions,” Kazemian said, “my team has been researching innovative waterless planetary construction 3D printing processes, utilizing the existing resources on the moon and Mars.”

One newer option is developing a printable concrete made up of molten sulfur and regolith, or loose unconsolidated rock and dust that covers the entire lunar surface, and designing a 3D printing machine capable of working with this challenging material, he said.

“We successfully overcame these challenges,” he said.

In the process, the LSU team discovered that sulfur-regolith concrete has a unique ability to be recycled without any loss in strength, allowing it to be remelted and reprinted. This has significant implications for cost savings, sustainability, and the conservation of energy and limited planetary resources, Kazemian said.

After several years of research on sulfur-regolith concrete, with support from NASA and the National Science Foundation, the LSU team is now making progress toward large-scale testing and studies using simulated lunar and Martian regolith.

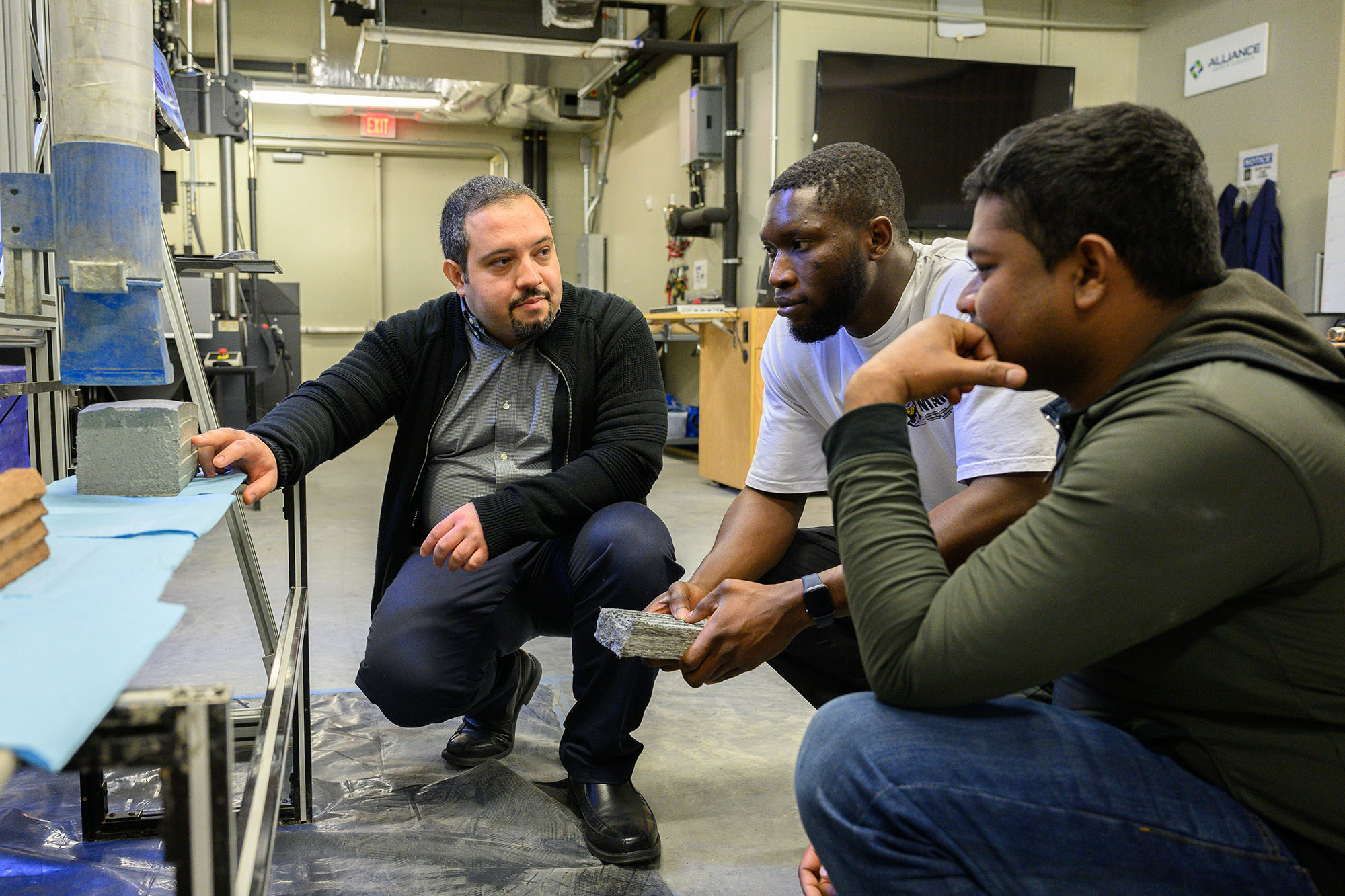

“Together with two of my PhD students, Ilerioluwa Giwa and Kasra Banijamali, we designed a customized extrusion system and installed it on a large robotic platform at NASA Marshall Space Flight Center in Alabama,” Kazemian said. “Our NASA collaborators are currently optimizing the printing process in preparation for more advanced joint studies and experimentation.”

‘To Benefit Our Community & Nation’

Kazemian began researching this technology as a Ph.D. student at the University of Southern California under Professor Behrokh Khoshnevis, widely considered the founding father of construction 3D printing.

In 2014, few researchers were exploring the technology, often dismissing it as impractical. However, Kazemian became fascinated by the future possibilities it presented, eventually dedicating his career to advancing robotic construction technologies and promoting their widespread adoption.

At LSU’s Bert S. Turner Department of Construction Management, he found a dynamic and growing academic department with a great reputation and strong ties to the construction industry.

“The supportive environment, existing facilities, and unique possibilities for collaboration with experts in different areas were the key factors that motivated me to join LSU,” he said. “Over the past four years, I have received unwavering support from my department and LSU College of Engineering, and I am very proud of the accomplishments my research group has achieved so far.

“We have ambitious plans to continue making significant contributions to the field of construction automation and to facilitate the industry’s adoption of robotic construction, to benefit our community and the nation.”

A Team From a Range of Disciplines

The research team consists of graduate and undergraduate students from a range of disciplines, including construction management, mechanical engineering, electrical engineering, computer science, and civil engineering.

“The ... multidisciplinary nature of our team has significantly helped us in finding novel solutions to the real-world problems in robotic 3D printing,” Kazemian said. “We go beyond construction and civil engineering boundaries to find creative solutions and explore new robotic capabilities that didn’t exist before.”

Banijamali, a Ph.D. candidate in Construction Management, says the exposure to this cutting-edge technology has profoundly shaped his career goals.

“The novelty of automated 3D-printed construction has opened my eyes to the vast possibilities of using robotics and automation to solve long-standing challenges in this field,” he said. “I am determined to continue exploring how these advanced technologies can be refined and implemented across various sectors, pushing the boundaries of what is possible within the construction industry.”

Kazemian also collaborates with multiple colleagues from construction management and other engineering and non-engineering departments, to explore new robotic construction paradigms.

He is also a member of a team led by Suniti Karunatillake of the Department of Geology & Geophysics and supported by the Provost's Fund for Innovation in Research with the goal of establishing a mission to Mars to investigate the geology and habitability of Martian glaciers. This is an extensive effort led by LSU, spanning four NASA centers, a national lab, a European space center, and two space companies.

Next Steps

Let LSU put you on a path to success! With 330+ undergraduate programs, 70 master's programs, and over 50 doctoral programs, we have a degree for you.